DESIGN

SLICE

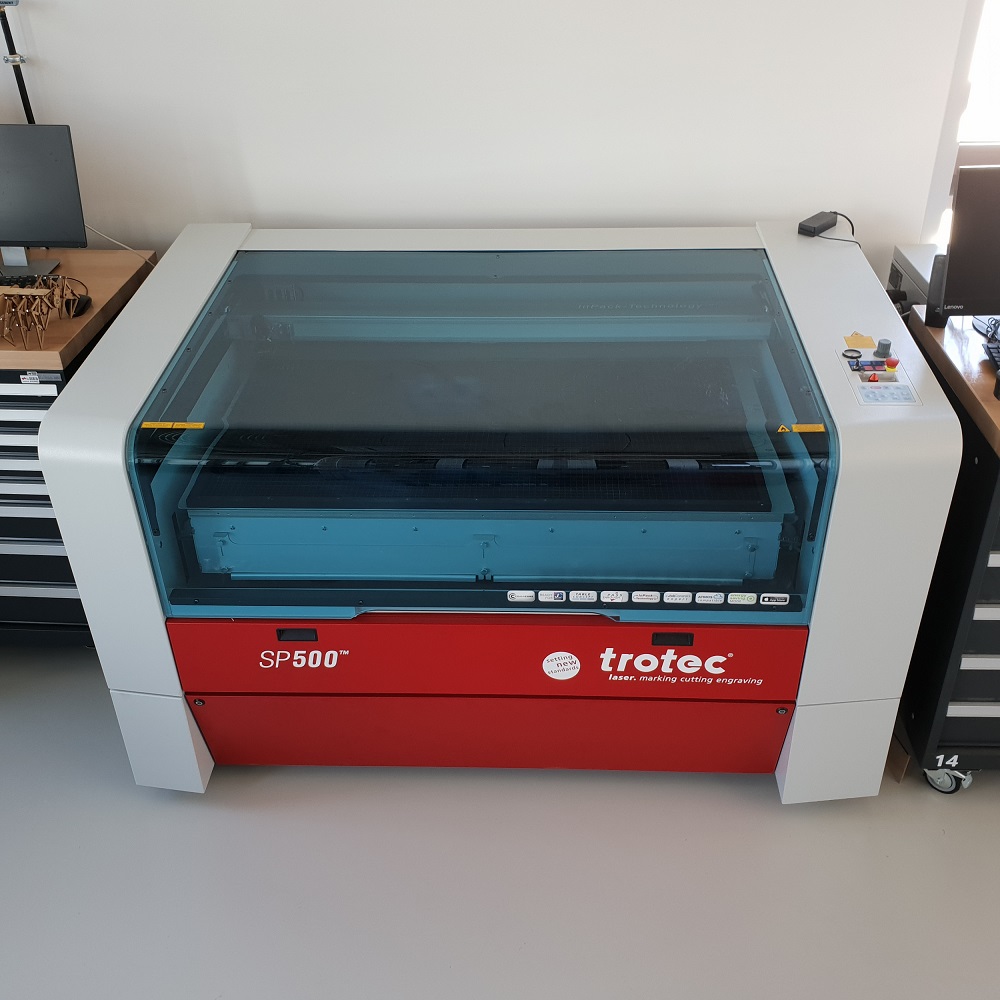

| availible technologies |  |  |  |

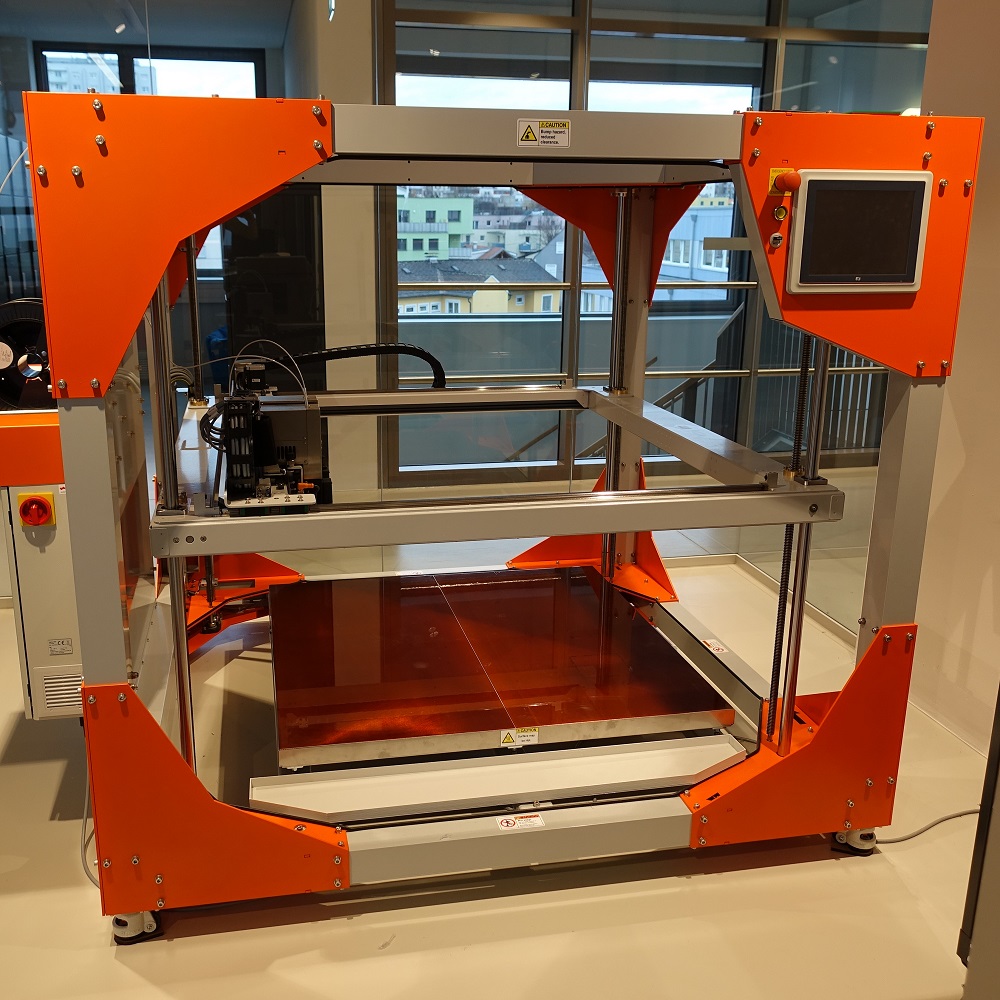

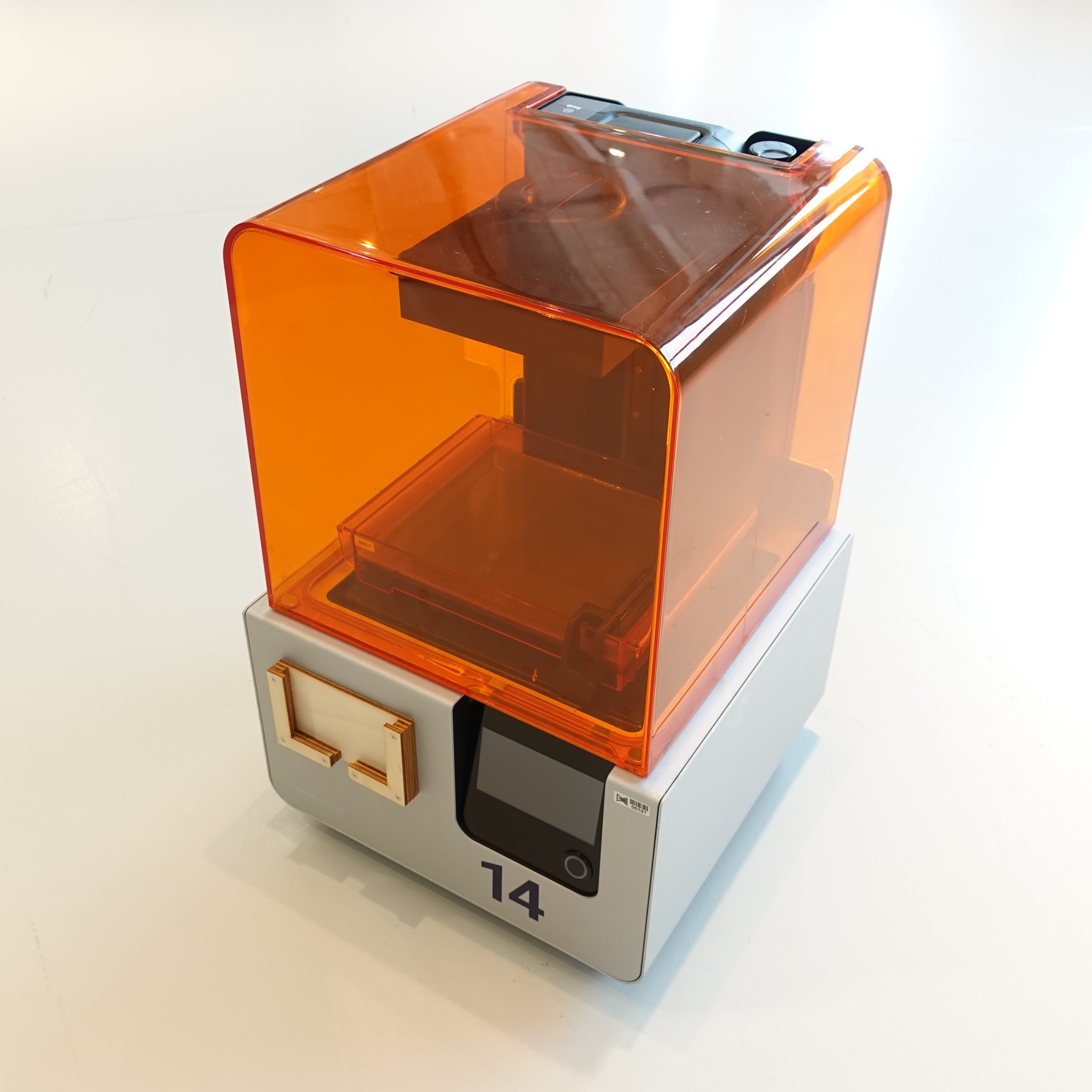

| FDM - Standard | FDM - Large Scale | SLA | |

| max. build-volume W x D x H | 200 x ∞ x 170 [mm] | 1000 x 1000 x 1000 [mm] | 145 x 145 x 175 [mm] |

| layer-height | 0,1 - 0,25 [mm] | 0,3 - 0,8 [mm] | 0,100 [mm] - 100 µm 0,050 [mm] - 50 µm 0,025 [mm] - 25 µm |

| materials | PLA PET-G TPU - Shore A70 - A98 bio- compatible PLA | PLA PET-G | photo-reactive resin - clear & grey heat resistant resin |

| application field & properties (recommendation) |

|

|

|

Data - preparation

Required file format for all our 3D-printers:

.STL

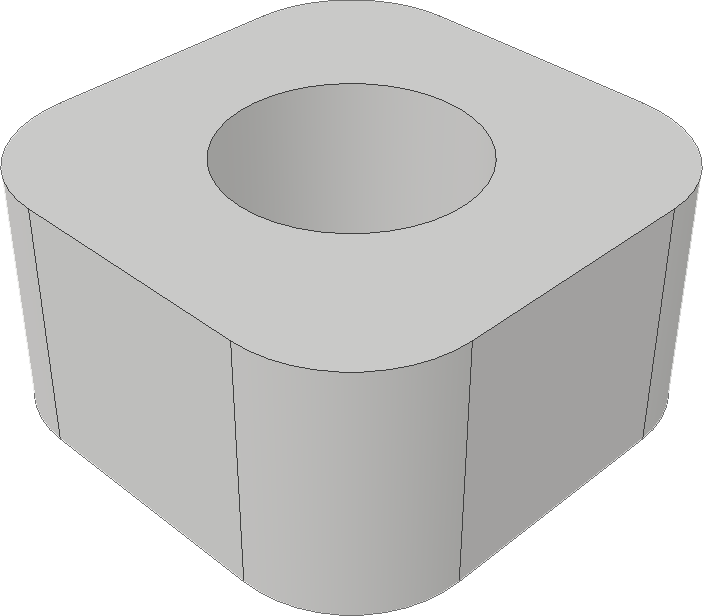

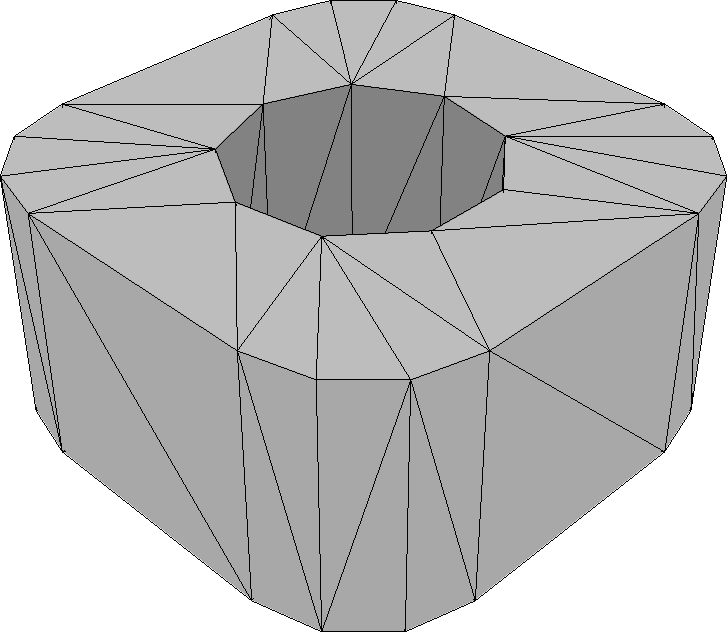

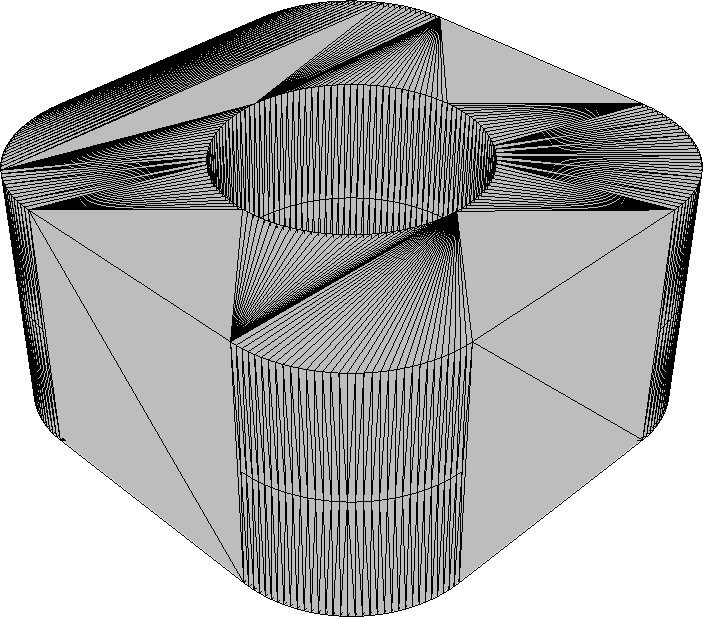

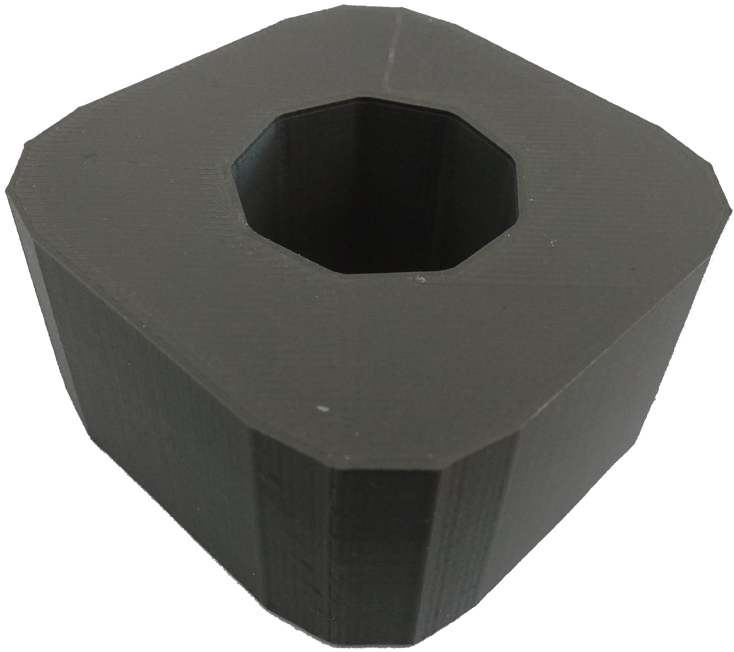

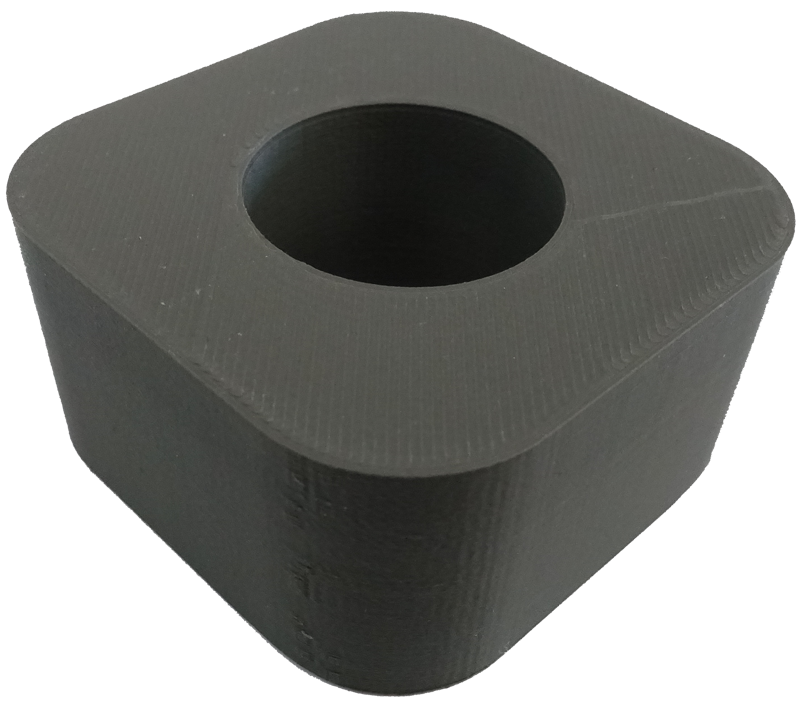

A 3D-printer manufactures an object based on a 3D-model. This model can be designed in any 3D-design or CAD software you like. It is important to export your design in the format .STL, which is compatible with all our 3D-printers and almost every 3D-printer out there. The .STL-export of your model converts the actual shape into a shape composed of triangular elements. Increasing the quality settings of your export means that more triangles are used to approximate the original design. In the picture below you can see a low and a high quality export with their resulting prints. Using a low quality .STL file will result in a print with significant deviations. Whereas the print result of the high quality export is quite similar to the original CAD design.

Original

CAD File

LOW quality

.STL export

HIGH quality

.STL export

Printed Results →

Print Technologies

FDM

Fused Deposition ModelingThis type of 3D-printer heats up a plastic filament in a nozzle until it melts. By moving the nozzle and extruding the materail it creates a model layer by layer

If you wish to know more about how FDM printing works check out this video.

SLA

StereolitographyThis type of 3D-printer uses a liquid resin as a material. The base is immerses into the resin where a UV laser then hits the material and solidifies it. This is done for each layer until the model is finished.

If you wish to know more about how SLA printing works check out this video.

Materials

Each 3D-printing technology has different advantages and disadvantages, as well as there are various materials with different properties available for each technology. To give you an overview and help you selecting the right material and technology for your needs, we listed our available materials, ranked their properties, and quantified some important characteristics.

FDM | SLA |

|||||

| Material | PLA | PETG | niceBIO | TPU | Resin | HT Resin |

| Colors | ■■□■■ ■■■■■ | ■■□ | ■■■ | ■ | ▨■ | ▨ |

| Detail Quality | ●● | ●● | ●● | ● | ●●● | ●●● |

| Flexibility | - | ● | - | ●● / ●●● | - | - |

| Temp. Resistance | ● (~55°C) | ● / ●● | ●● (~145°C) | ● / ●● | ● | ●●● (~235°C) |

| UV Resistance | ●● | ●● | ●● | ●● | ● | ● |

| Spezial Properties | FDA - Confirm | Shore A70 / A82 / A95 | produce injection molds | |||

| Documents | Datasheet | Datasheet | Datasheet | Datasheet_A70 Datasheet_A82 Datasheet_A95 | Tech Data Sheet Safety Data Sheet | Tech Data Sheet Safety Data Sheet |

These values are based on our experience and only represent a rough guideline. We do not guarantee their accuracy. The colors show just our basic assortment and you can always ask our staff about other colors on stock.