Makerthon #9

May, 21st 1:00pm until May, 23rd

48 Hours

3 Interdisciplinary Teams

1 Challenge

Take the chance to gain hands-on experience on product development based on the design thinking approach.

We are looking for passionate Makers who want to work together in interdisciplinary teams on a real-life challenge from the industry in the field of “(electric vehicle) battery safety”.

The Makerthon takes place at the Schumpeter Laboratory for Innovation.

Challenge: Re-purposing for new application areas / business fields for AVL Stingray™

Key Facts AVL

-

Leading R&D expert in the

areas of Automotive

Powertrains, Drivetrain

Solutions, Simulation &

Testing -

> 11.000 employees

worldwide - Fields of Expertise:

- Testing Solutions

- Simulation Technologies

- ADAS and Autonomous Driving

- Battery

- Calibration

- Controls and Electronics

- E-Drive

- Engineering Services

Situation / Object

Rising number of EVs in all areas leads to…

-

Increasing risk of thermal runaway for testbed operators / fire fighting personnel / workshops / warehouses / ferries / heavy duty / homes & co.

-

EV HV-batteries are very hard to control; Common methods are neither effective nor efficient

-

AVL has developed HV-battery fire suppression systems to control thermal runaways

- New solutions for new application areas (ongoing electrification) are wanted / sought for

- Bus / Trucks / Trains

- Heavy duty / Forklifts

- Ships / Ferries / …

Tasks / Objectives

Analyze at least one electrified vehicle / machine / device and develop a physical concept / prototype how AVL Stingray™ can be re-purposed / adapted or implemented / integrated to suppress a potential battery fire

-

Where is the battery located / what needs to be considered (e.g., enclosure thickness, battery setup, location)?

-

How can penetration units be applied /attached to the battery (integrated)?

-

Local storage of extinguishing media needed / possible? Where can it be stored (amount)?

-

Ideas for improvement of the working principle / set-up / re-purposing of AVL Stingray™?

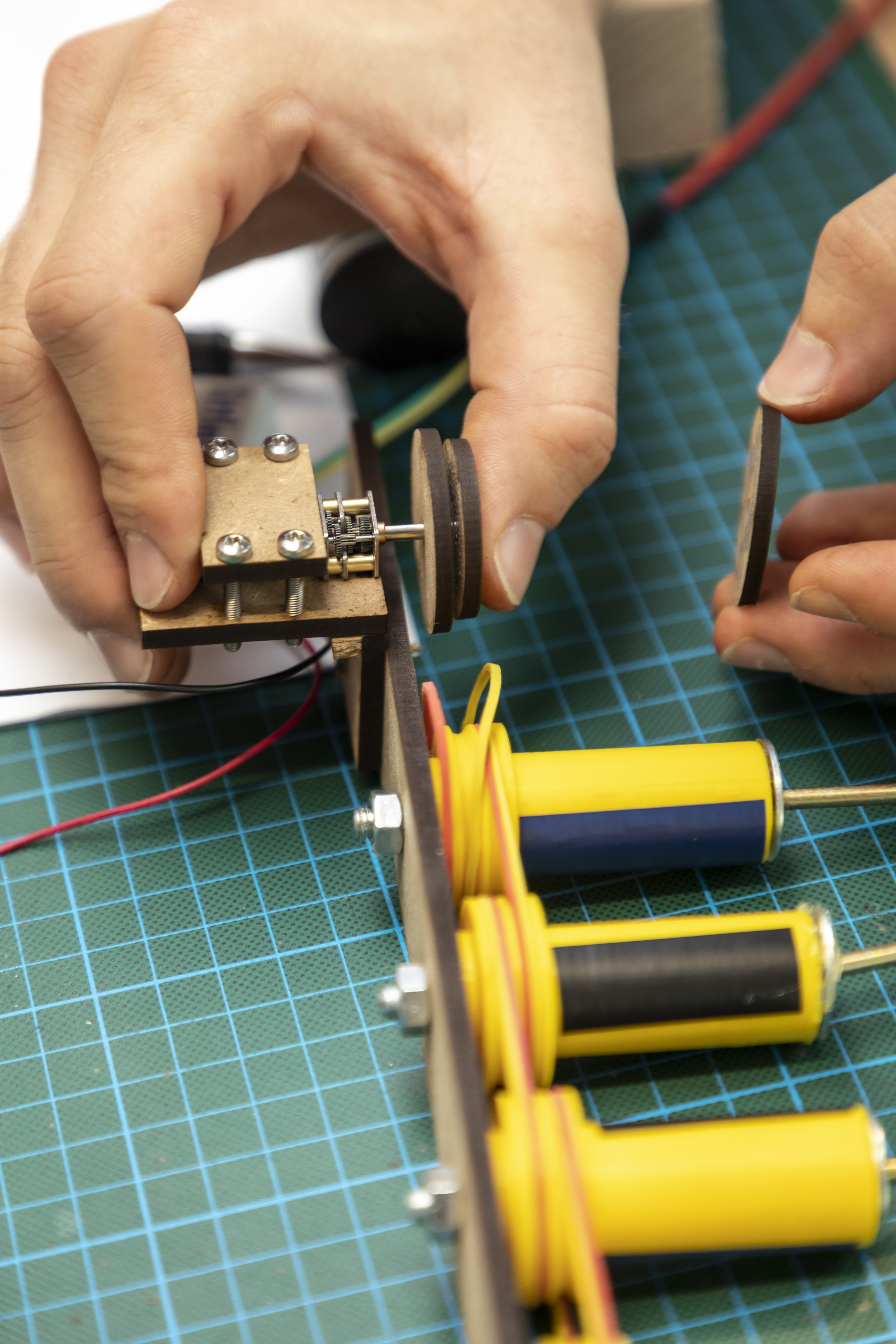

Impressions from Makerthon #2

Frequently Asked Questions

Location

The Makerthone takes place in the Schumpeter Laboratory for Innovation, Inffeldgasse 11, 3 8010 Graz.