Makerthon #7

November, 23rd 1:00pm until November, 25th

48 Hours

6 Interdisciplinary Teams

1 Challenge

Take the chance to gain hands-on experience on product development based on the design thinking approach.

We are looking for passionate Makers who want to face real life challenges from industry in the fields of “Electrification” and “personal care consumer products” in interdisciplinary teams.

Get the challenge - find ideas - develop concepts and build a prototype - use your skills and motivation to beat the challenge!

The Makerthon takes place at the Schumpeter Laboratory for Innovation.

Challenge:

Fuel Flow Rate Measurement - the next Generation

Key Facts AVL

-

Leading R&D expert in the areas of Automotive Powertrains, Drivetrain Solutions, Simulation & Testing

-

With more than 11.000 employees worldwide

-

Fields of Expertise:

- Testing Solutions

- Simulation Technologies

- ADAS and Autonomous Driving

- Battery

- Calibration

- Controls and Electronics

- E-Drive

- Engineering Services

Situation / Object

- Increasing technical complexity, as well as stricter environmental and legal requirements, makes modern vehicle development a challenge

- Manufacturers in the heavy-duty and Non-Road Mobile Machinery (NRMM) industry are forced to focus on topics such as CO2 reduction, fuel economy optimization, and real-life fuel consumption

- AVL FuelTron M.O.V.E is most actual generation of onboard fuel consumption measuring systems, aiming for being the industry standard for fuel consumption measurement in these industries.

Tasks / Objectives

- Analyze the functionality (Function Analysis) of the mobile measurement system for onboard fuel consumption measurement for the heavy-duty and non-road mobile machinery industry

- Optimize the existing FuelTron MOVE under consideration of:

- Weight reduction by using new and alternative manufacturing methods, such as additive manufacturing

- Optimized functionality

- Optimized packaging

- Enhanced environmental requirements (vibration, shock, temperature)

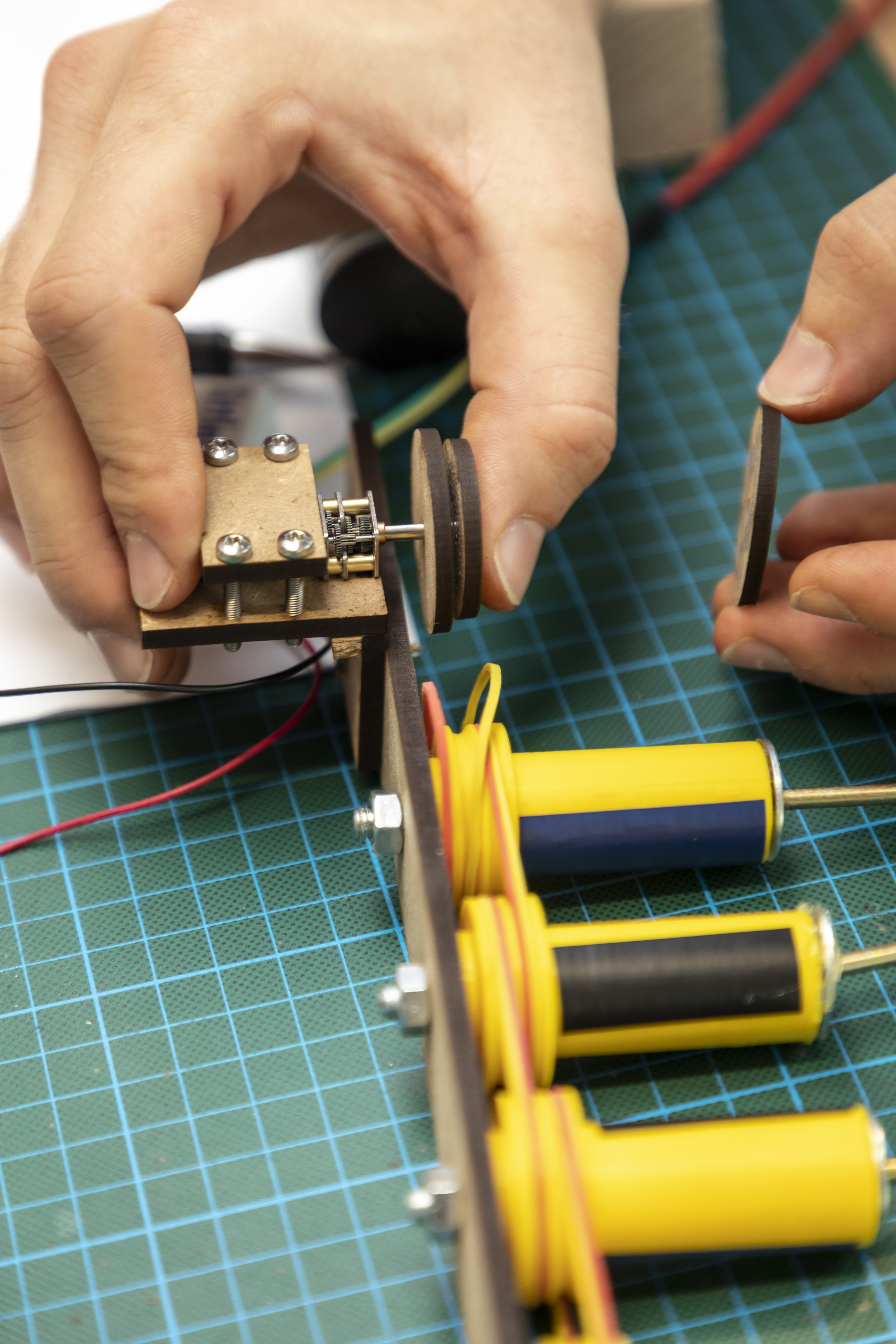

Impressions from Makerthon #2

Frequently Asked Questions

Feel free to call us our write an email if any unanswered questions come to your mind.

Location

The Makerthone takes place in the Schumpeter Laboratory for Innovation, Inffeldgasse 11, 3 8010 Graz.